优势

专业化的研发设计能力 系统化的项目管理能力 标准化的设备管理流程

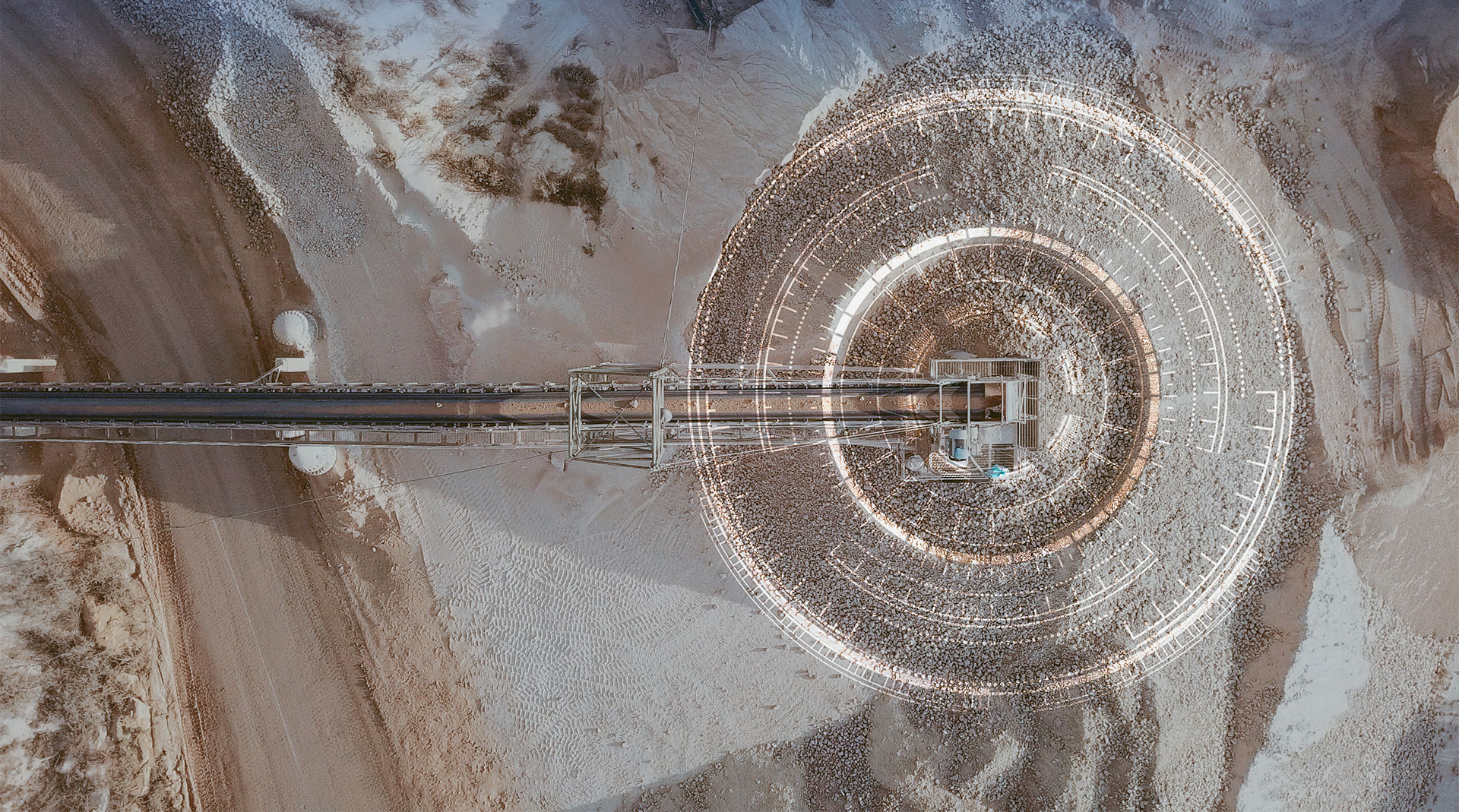

Intelligent Conveying Full Stack Solution

Targeting industrial bulk material transportation sites, we provide users with management application systems necessary for daily production and operation processes to improve their on-site lean management level. Including: intelligent point inspection, intelligent online monitoring, general contracting service management, cockpit management, industrial big data analysis, etc.

Relying on Baotong Cloud Computing Services, we provide leading one-stop service solutions for industries such as mining, steel smelting, building materials and cement, port terminals, and thermal power generation. Realize real-time perception of sensor/edge computing and IoT platform linkage, reduce security risk and network pressure, and ensure high availability of business. Provide a one-stop service that integrates design, construction, and operation, achieving efficient application deployment, upgrading, configuration, and scalability capabilities, and comprehensively assisting users in intelligent construction.